- 1

- 2

- 3

- 4

- 5

- 6

*When no country data is available the EU28 average value is given

This project has received funding from the European Union’s Horizon 2020 Research and Innovation program under Grant Agreement n° 680738

Disclaimer

This report (“Report”) is prepared and issued by the Indus3Es tool developers for the user named on the cover page (the “User”).

The results generated by the Indus3Es tool provide a first indication on the possibilities to implement an absorption heat transformer at the User’s industrial process, however actual numbers may be different. This tool has been compiled with the greatest possible care, but no rights may be derived from its content. The Indus3Es tool developers shall have no liability to third parties in connection with this Report or for any use whatsoever by third parties of this Report.

Introduction

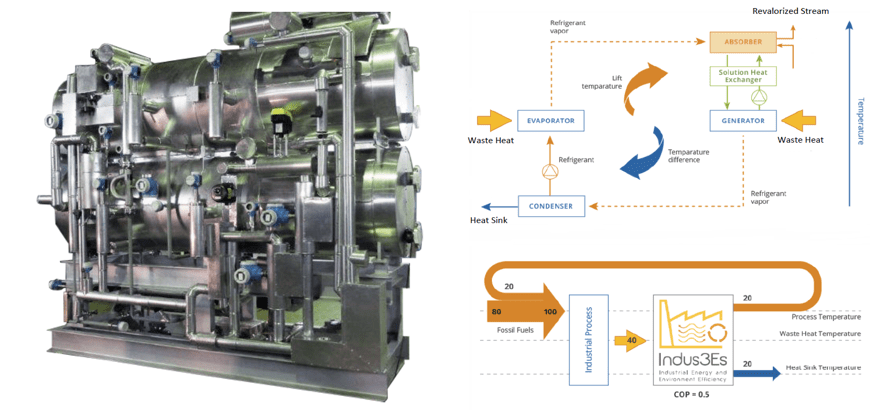

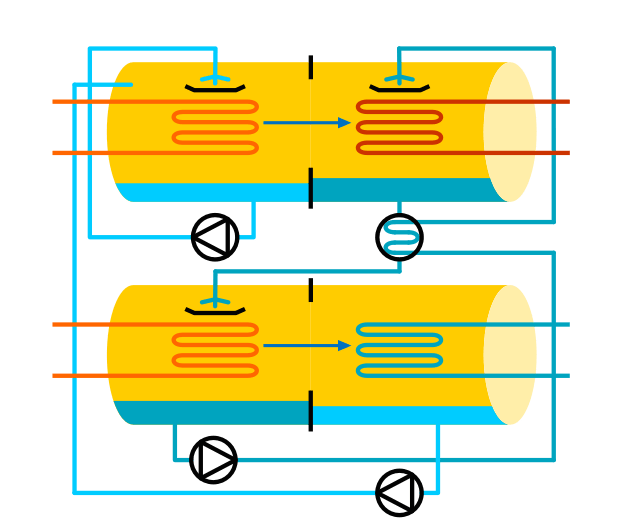

Energy-Intensive Indus3Es need to reduce their primary energy consumption in order to increase their effectiveness. This would lead to an increase in their competitiveness and a reduction of their product’s embedded energy and carbon footprint. Absorption Heat Transformers (AHT) are designed to recover and revalorize industrial waste heat below 130°C. AHT revalorizes almost 50% of recovered waste heat, boosting the temperature and becoming usable in the industrial process again.

The aim of this report is to analyse the feasibility to implement the Indus3Es AHT technology in your industrial process. Based on the entered characteristics of your waste heat streams, the tool has calculated the operation and implementation costs of AHTs in your processes, as well as the resulting savings and associated return of investment.

User Defined AHT Process

This section presents the parameters of the industrial process and associated waste stream defined by the User.

Results

This section presents the results of the AHT feasibility assessment, including the main design parameters of the AHT, costs and savings, investment costs and financial results.

(*) These include EPC costs associated with required works and equipment to integrate the AHT in the industrial process. These costs have been estimated to be 40% of the total cost of the AHT.

(**) A 2% inflation rate has been considered to calculate the AHT’s financial indicators over a project lifetime of 20 years

(***) Maintenance costs have been estimated as a 2% of the total investment costs.

Sensitivity of AHT’s financial feasibility to operational temperature

It is interesting that the user understands the effects that the outlet temperature has on the financial feasibility of the AHT implementation to their industrial process. As such, the following table presents the heat delivered, fuel savings, payback period, IRR and NPV correspondent to the set AHT outlet temperature and for three additional temperatures closed to the value set by the user (set outlet temperature -5, -10 and -15 °C).

*When no country data is available the EU28 average value is given